Lithium sulfide (Li2S): new opportunities for sulfide all-solid-state batteries

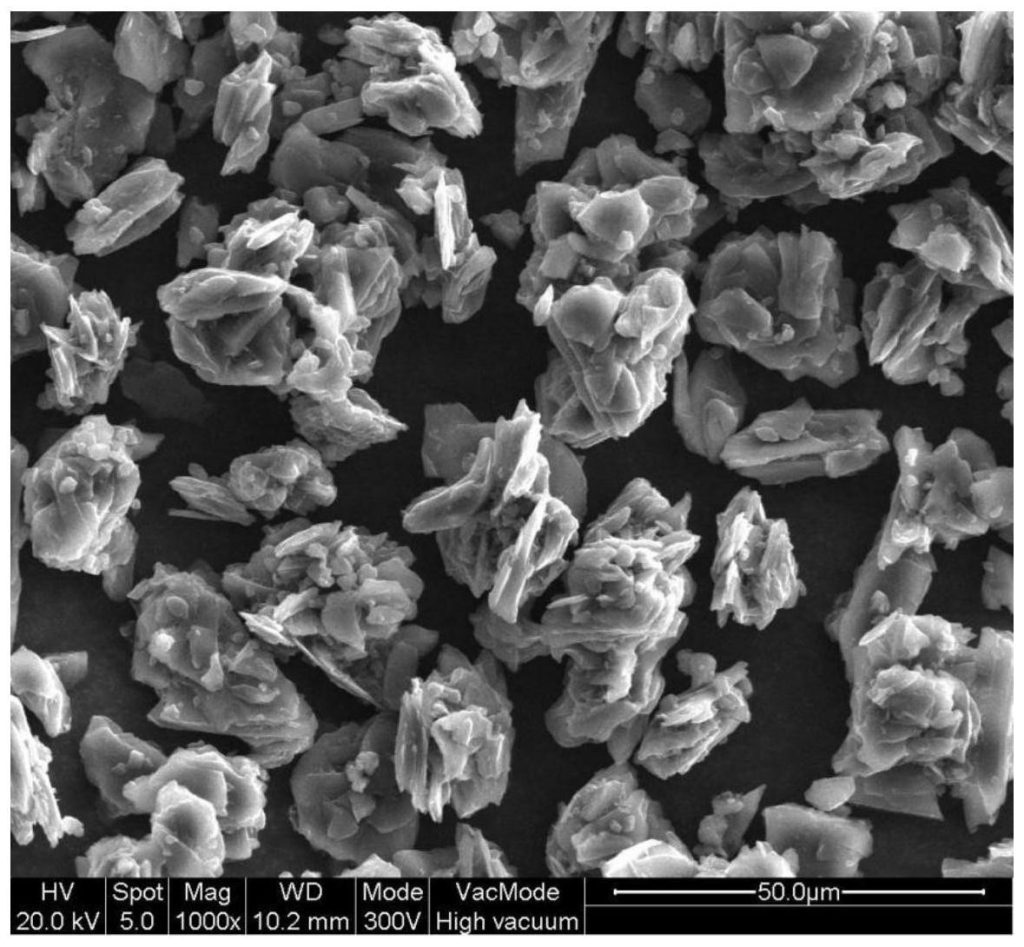

In the next generation of advanced secondary battery technology, all-solid-state lithium batteries and lithium-sulfur batteries are the two main development systems. Sulfide all-solid-state batteries use safe, non-flammable solid electrolytes. This helps fix safety issues found in batteries with organic electrolytes. Lithium-sulfur batteries feature lithium metal as the negative electrode. They use sulfur or lithium sulfide […]

Lithium sulfide (Li2S): new opportunities for sulfide all-solid-state batteries Read More »