HELP YOU DEVELOP

LITHIUM-ION BATTERIES

WITH STRONGER FUNCTIONS, GREATER CAPACITY, LONGER LIFE, SHORTER CHARGING TIMES, AND LIGHTER WEIGHT.

WELCOME TO COMPANY

EPIC POWDER Makes World Better

20+ years of work experience in the ultrafine powder industry

Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder

Advisory

Dedicated personnel are responsible for technical support and answering demand information.

Program

Provide detailed technical solution reports based on customer requirements and products

Assembly

The business specialist updates the production schedule weekly to report to customers

Check

After internal acceptance, send the acceptance materials to the customer via email and notify them to schedule a time for factory acceptance

CATHODE MATERIALS PROCESSING TECHNOLOGY

Lithium compounds used in lithium batteries have specific particle size distribution requirements

GRAPHITE ANODE MATERIALS PROCESSING TECHNOLOGY

Carbon material is currently the main negative electrode material used in lithium-ion batteries

SILICON-CARBON ANODE MATERIALS PROCESSING TECHNOLOGY

Among advanced anode materials applied to lithium-ion batteries, silicon–carbon anodes have been

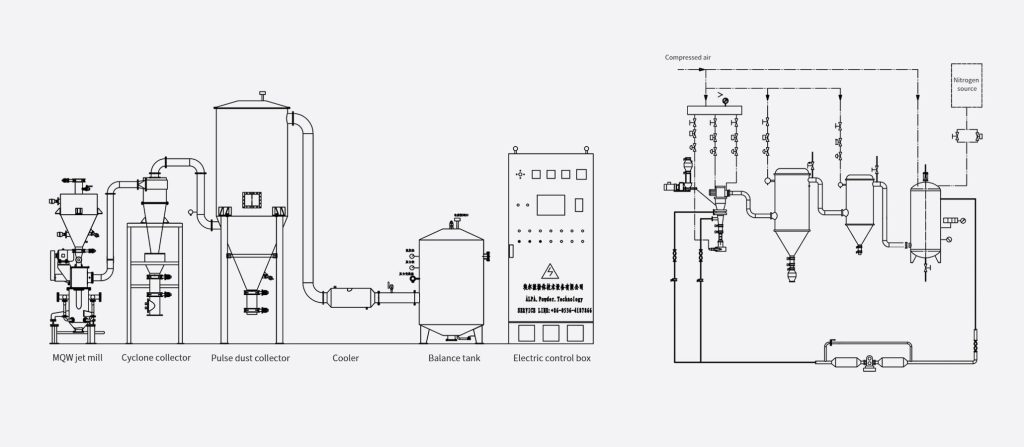

Ceramic-lined and Gas Closed Loop Protection System

Lining with ceramic and polyurethane materials of equipment, increase of magnetic material in the production process is <20PPB.

The whole production line uses closed and cycle system. The closed environment effectively isolates moisture from the air, moisture increment in the production process is <50PPM. In some circumstances, inert atmosphere gases (N2, Ar, CO2, etc.) can be used.

Related articles

Request a Quote

Please fill in the form below.

Our experts will contact you within 6 hours to discuss your needs for machine and processes.

Factory Address:

NO. 369, Road S209, Huanxiu , Qingdao City, China